Electroplated Aluminum Brazing

Assemblies that mix Al alloys with other materials are notoriously difficult to manufacture. Welding, joining and brazing of aluminum is difficult and sometimes considered an art. Brazing aluminum to other materials adds to the complexity and difficulty of the assembly process. Pure electroplated aluminum can be used to tackle many difficult welding and brazing challenges.

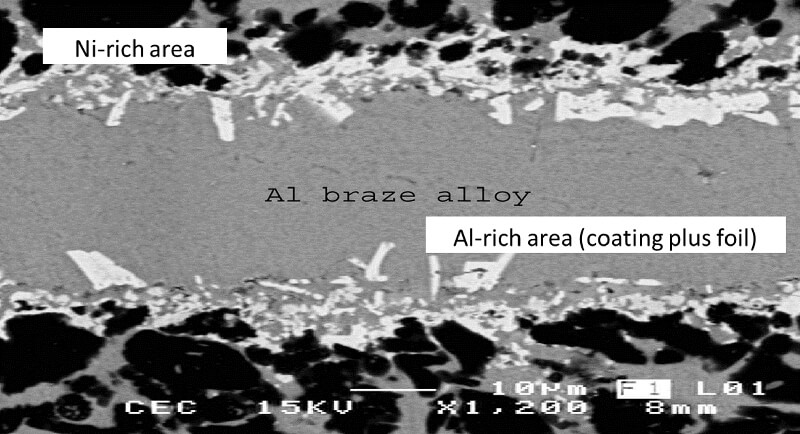

The aluminum plating can be deposited on dissimilar materials transforming the assembly surface into one uniform material, alleviating brazing concerns and expanding the available joining processes that can be used. Electroplated aluminum brazing is not affected by the inclusions and impurities of other braze enablers, that can turn into slag and lessen the braze integrity. Complex assemblies requiring brazed joints of multiple materials can be manufactured using existing proven techniques for aluminum.

Contact us for more information on aluminum brazing or to discuss your application in more detail.